Before we can even start to debate what makes a good system, we need to first establish what parts define system performance. The most important thing to consider is the supply and return water temperature from and back to the energy centre. This requirement, along with the HIU duty, starts to define the performance of the heat exchanger that are to be used for the domestic hot water and heating.

To maximise the heating water provided by the energy centre, the heat exchangers should be selected to match the heating water supply temperature as closely as possible. This match is called the ‘pinch point’. The closer the two points, the lower the supply water temperature needs to be.

Closing the gap between the primary heating mains water temperature and domestic hot water temperature is a choice between performance and cost. Basically, the closer the two temperatures are to each other the larger and more expensive the plate heat exchanger. If a Heat Interface Unit is sized with the flow and return temperatures of the water distribution system, it is more likely that better design temperatures can be achieved than just installing a standard ‘one heat exchanger suits all’ approach.

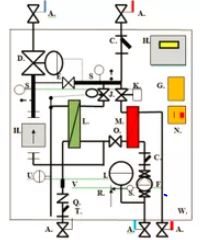

To maximise the life of the HIU, a flushing by-pass, drain and inline magnetic filter need to be included. A flushing by-pass assists to ensure the correct design conditions as dirt and debris are flushed clear. The drain gives the Commissioning Engineer the ability to check the pipes have been properly flushed, and the inline magnetic filter adds some additional protection, provided the water system is maintained and the unit is serviced.

Good design practice for the HIU will include a device to regulate and control pressure differences across the heat exchangers, unless the system has been designed for low pressure drops across all units, as with a thermal grid. Failure to control pressure difference across a heat exchanger will influence the heat exchanger’s performance. A differential pressure control valve (DPCV) works for large and small systems where large differential pressures exist. Large pressure differences between the primary supply and the controlled pressure difference to the HIU will influence the type, model and range of the DPCV to be selected. This should be checked and the most suitable DPCV provided as one model may not fit all systems. Pressure independent control valves (PICVs) can be used in single building systems and with DPCVs. The use of PICVs allows for electronic control and monitoring.

There is so much more to consider but a well-designed system is vital to maintain the long term welfare of the unit and to maximise energy efficiency. For more information and help please contact us.